Rm 2rh sau biyu tashar imc thermorming inji

Sigogi na inji

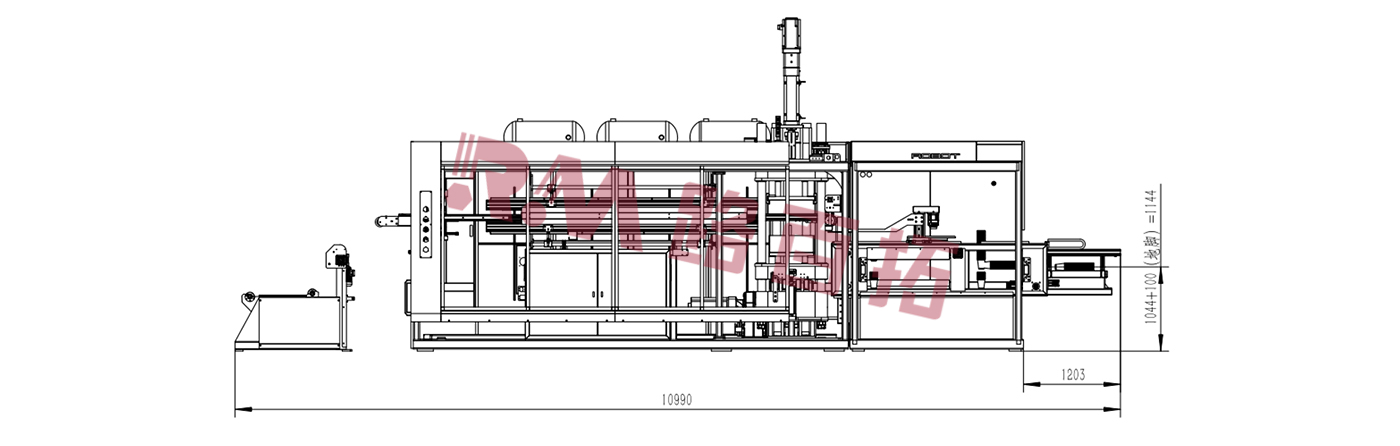

| ◆ Misali: | Rm-2r |

| ◆ Max.forming yanki: | 820 * 60mm |

| ◆ Max.foring tsawo: | 80mm |

| ◆ Max.sheet kauri (mm): | 2mm |

| ◆ Max Strike (Bar): | 8 |

| Hoton mai laushi na Dry: | 48 / Cyl |

| ◆ Tasiri karfi: | 65t |

| ◆ Voltage: | 380v |

| PLC: | Kenewa |

| ◆ Servo Motar: | Yaskawa |

| ◆ Resoler: | Gnord |

| Aikace-aikacen: | trays, kwantena, akwatuna, lids, da dai sauransu. |

| ◆ Core abubuwan haɗin: | PLC, injin, ɗauka, Gearbox, Motar, Motoci, Matsa |

| ◆ abu mai dacewa: | Pp.ps.pet.pet.pos.pla |

| Max. M Girma | Clamping karfi | Saurin zagaye | Max. Zanen gado Gwiɓi | Max.foming Tsawo | Max.ir Matsa lambu | Abubuwan da ya dace |

| 820x620mm | 85t | 48 / sake zagayowar | 2.8mm | 180mm | 8 mashaya | PP, PS, dabbobi, dabbobi, zaƙa, os, pla |

Bidiyo na samfuri

Aikin Takardar Aiki

Babban fasali

Kwarewa wani sabon matakin aiki tare da Injin-Ingilishi na atomatik form mai saurin aiki da injin yankan. Nemi wani tsari na tashoshi biyu, yana yin forming da yankan lokaci guda, yana da haɓaka haɓakar haɓakawa. Tsarin in-mutu yana tabbatar da sauri da kuma tabbataccen yanke abubuwa, yin tsarin samarwa sosai.

Model na ✦er yana ba da tabbatacce duka da ƙarancin matsin lamba. Ta amfani da zafi da matsin lamba, an canza zanen filastik zuwa siffar samfurin da ake so. Kyakkyawan matsin lamba na tsari yana ba da tabbacin farfajiya mai kyau, yayin da mummunan matsin lamba yake tabbatar da daidaitaccen sifofin concave da kuma siffofin fasali, wanda ya haifar da ingantaccen ingancin samfurin.

Tsarin pallet na kan layi, injinmu ya sami damar sarrafa kayan aiki ta atomatik. Wannan tsari mai daidaitawa yana inganta haɓaka samarwa da kuma rage ƙarfin aiki, yana ba da damar ƙungiyar ku don mai da hankali ga wasu mahimman ayyuka.

Ana dacewa da injin da yake dacewa don samar da ƙananan samfuran gyada, faranti, da kuma lids. Koyaya, zai iya sauƙaƙe daidaitawa ga samfuran samfuri daban-daban. Ta hanyar canza molds da daidaita sigogi, ana iya samar da kewayon samfurori da yawa.

Envest a cikin inganci da inganci tare da ingancin saurin haɓaka da injin yankan da aka yankewa. Tsarin lokaci ɗaya da yankewa, ingantacce mai kyau da mara kyau, stacking mai sarrafa kansa, da sassauci a cikin samar da samfurin - duka a cikin mafita ɗaya mai ƙarfi. Za a ci gaba da gasar kuma ya ɗaukaka karfin masana'antar ku tare da injin yankan mu!

Yankin aikace-aikace

Wannan injin thermorming na tashar jirgin sama ana amfani dashi sosai a cikin marufin abinci da masana'antu na abinci. Tare da fa'idodi da sassauci, yana samar da kamfanoni tare da mafi inganci da mafita mafi inganci.

Koyawa

Gabatarwa:

Thermofing wani tsari ne mai tsari da ingantaccen tsari da ake amfani da shi a saman masana'antu daban daban. Don tabbatar da samarwa da inganci da inganci mai mahimmanci, ingantaccen kayan aiki, albarkatun kayan aiki, da kiyayewa suna da mahimmanci.

Aikin kayan aiki:

Kafin fara samarwa, tabbatar da dogaro da wutar lantarki ta injin dinka na 2. Gudanar da cikakken bincike na dumama, sanyaya, tsarin matsin lamba, da sauran ayyuka don tabbatar da aikinsu na yau da kullun. Dare shigar da molds da ake buƙata, tabbatar da cewa an haɗa su da su hana duk wani yiwuwar rashin hankali a lokacin masana'antar.

Raw kayan aiki:

Fara ta hanyar zaɓi takardar filastik ya dace da haɗi, tabbatar da shi yana canzawa tare da takamaiman buƙatun aikin. Kula da hankali ga girman da kauri, kamar yadda waɗannan abubuwan suna da muhimmanci sosai amincin samfurin. Tare da takardar filastik mai kyau, zaku shimfiɗa harsashin ginin rashin ƙarewa mara amfani.

Saitunan zafi:

Bude madaidaicin ikon sarrafa injin ɗinku kuma saita zafin jiki da lokaci. Yi la'akari da halaye na kayan filastik da keɓaɓɓen buƙatu lokacin yin waɗannan gyare-gyare. Bada izinin injin thermorming lokaci don isa zafin jiki na, tabbatar da kayan filastik ya kai ga sananniyar sutura da ake so.

Forming - stacking:

A hankali sanya takardar filastik mai preheated akan mold surface m, tabbatar da shi ya ta'allaka ne da santsi. Fara da tsarin da ake amfani da shi don amfani da matsi da zafi a cikin firam lokaci, da fasaha mai haskaka takardar da ake so. Faɗin Post-foring, bari filayen filastik ƙarfafa da sanyi ta hanyar mold, ci gaba zuwa tsarin tsari mai tsari don ingantaccen palletized.

Fitar da samfurin da aka gama:

Daidaitaccen Binciken kowane samfurin da aka gama don tabbatar da cewa siffar da ake buƙata da kuma adenawa ga ƙimar ƙimar. Wannan kimar kimantawa yana da tabbacin cewa mahalarta kawai basu bar layin samarwa ba, ta ceceda ka da kyau.

Tsaftacewa da kiyayewa:

Don kiyaye ingancin kayan aikin thermoforming, dauko da tsaftace tsaftacewa da tsarin aiki na yau da kullun. Bayan amfani, iko ƙasa da injin thermorming kuma cire shi daga tushen wutar lantarki. Gudanar da tsabtace tsabtace abinci da kayan aiki don kawar da kowane tsadar filastik ko tarkace. A kai a kai bincika abubuwanda kayan aiki daban-daban don tabbatar da ingantaccen aikin su, tabbatar da yawan aiki mai narkewa.