Barka da zuwa tuntuba da yin shawarwari

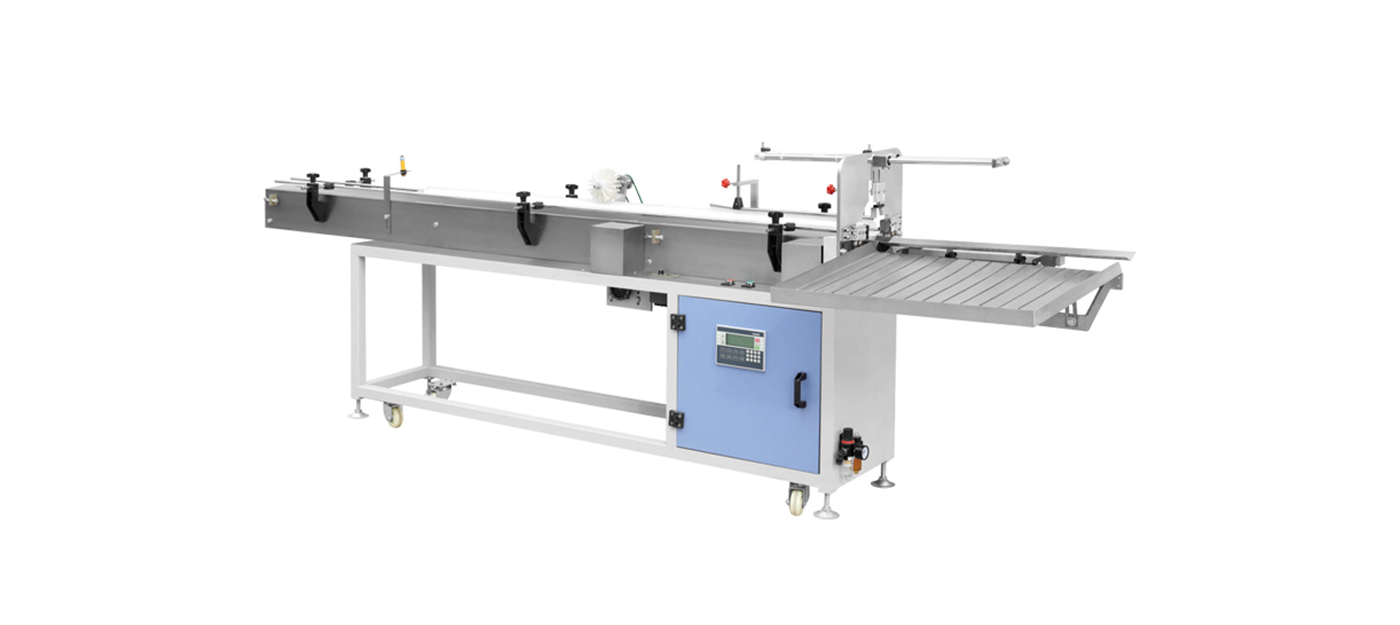

RM-4 Injin Thermoforming na Tasha Hudu

Bayani

The 4-tasha tabbatacce kuma korau matsa lamba thermoforming inji ne m samar da kayan aiki da za a iya amfani da su samar da yarwa filastik 'ya'yan itace kwalaye, flower tukwane, kofi kofin murfi da domed murfi tare da ramukan, da dai sauransu The kayan aiki sanye take da sauri mold canji tsarin da kuma yana da amfani da wani musamman dumama akwatin zane. Wannan kayan aiki yana ɗaukar fasahar thermoforming mai inganci da mara kyau don aiwatar da takardar filastik cikin sifar da ake buƙata, girman da ƙirar naushi daidai ta hanyar dumama takardar filastik da matsawa gas mai inganci da mara kyau. Wannan kayan aiki yana da nau'i hudu na wuraren aiki don kafawa, ƙwanƙwasa rami, ƙwanƙwasa gefen, da stacking da palletizing, wanda zai iya biyan bukatun masana'antu daban-daban kuma tabbatar da inganci da daidaito na samfurori.

Ma'aunin Na'ura

| Wurin yin gyare-gyare | Ƙarfin matsawa | Gudun gudu | Kaurin takarda | Tsawon kafa | Ƙirƙirar matsin lamba | Kayayyaki |

| Max. Mold Girma | Ƙarfin Ƙarfi | Busashen Gudun Zagaye | Max. Shet Kauri | Max.Foming Tsayi | Max.Air Matsin lamba | Dace Material |

| 820x620mm | 80T | 61/ sake zagayowar | 1.5mm | 100mm | 6 Bar | PP, PS, PET, CPET, OPS, PLA |

Siffofin

Ikon sarrafawa ta atomatik

Kayan aiki yana ɗaukar tsarin sarrafawa ta atomatik na ci gaba, wanda zai iya sarrafa daidaitattun sigogi kamar zafin jiki na dumama, lokacin gyare-gyare da matsa lamba don tabbatar da kwanciyar hankali da daidaito na tsarin gyare-gyare.

Canjin mold mai sauri

Na'urar thermoforming na 4-tashar tana sanye take da tsarin canji mai saurin canzawa, wanda ke sauƙaƙe saurin sauye-sauye kuma ya dace da buƙatun samar da samfuran daban-daban, don haka inganta haɓakar samarwa.

Ajiye makamashi

Kayan aikin sun rungumi fasahar ceton makamashi ta ci gaba, wanda ke rage yawan amfani da makamashi yadda ya kamata, yana rage farashin samar da kayayyaki, kuma yana da alaƙa da muhalli a lokaci guda.

Sauƙi don aiki

Na'urar thermoforming na 4-tashar tana sanye take da ƙirar aiki mai fahimta, wanda ke da sauƙin aiki da sauƙin koya, rage farashin horar da ma'aikata da ƙimar kuskuren samarwa.

Aikace-aikace

Ana amfani da injin thermoforming na tashar 4 a ko'ina a cikin masana'antar shirya kayan abinci, kuma ya dace musamman ga masana'antun da ke samar da samfuran filastik akan babban sikelin saboda ingancinsa, babban ƙarfi da sassauci.

Koyarwa