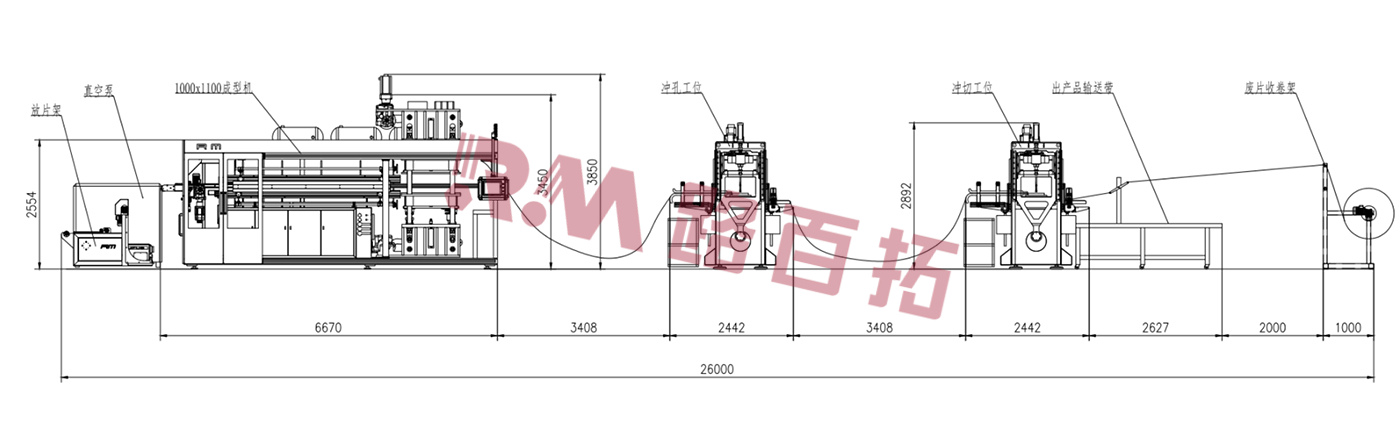

RM-T1011 + GC-7 + GK-7 Thermoforming Machine

Ma'aunin Na'ura

| ◆Model: | Saukewa: RM-T1011 |

| ◆Max. girman mold: | 1100mm × 1170mm |

| ◆Max. yankin kafa: | 1000mm × 1100mm |

| ◆Min. Yanki na ƙirƙira: | 560mm × 600mm |

| ◆Max. Yawan saurin samarwa: | ≤25Lokaci/min |

| ◆Max.Forming Tsawo: | 150mm |

| Faɗin takardar (mm): | 560mm-1200mm |

| ◆Tsarin motsi: | Matsakaicin bugun jini ≤220mm |

| ◆Max. karfi: | kafa-50T, naushi-7T da yankan-7T |

| ◆ Samar da wutar lantarki: | 300KW (ƙarfin zafi)+100KW (ikon aiki) = 400kw |

| ◆Ciki da naushi inji 20kw, sabon inji 30kw | |

| ◆ Bayani dalla-dalla na samar da wutar lantarki: | AC380v50Hz, 4P (100mm2+ 1PE (35mm2) |

| ◆Tsarin wayoyi biyar na waya uku | |

| ◆PLC: | KEYENCE |

| Motar Servo: | Yaskawa |

| ◆ Mai Ragewa: | GNORD |

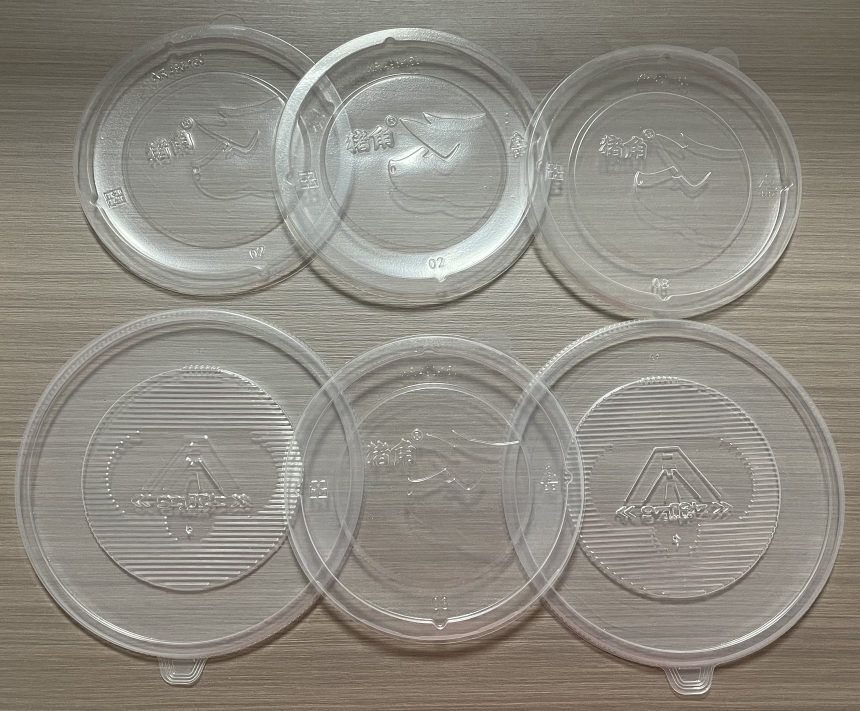

| ◆Aikace-aikace: | trays, kwantena, kwalaye, murfi, da sauransu. |

| ◆Abubuwan da ake buƙata: | PLC, Injin, Bearing, Gearbox, Motoci, Gear, famfo |

| ◆ Abubuwan Da Ya Dace: | PP.PS.PET.CPET.OPS.PLA |

| Max. Girman Motsi | Ƙarfin Ƙarfi | Ƙarfin Punch | Ƙarfin Yankewa | Max. Ƙirƙirar Tsawo | Max. Iska Matsi | Busashen Gudun Zagaye | Max. Buga/ Yanke Girma | Max. Buga/ Yanke Gudun Ciki | Dace Material |

| 1000*1100mm | 50T | 7T | 7T | 150mm | 6 Bar | 35r/min | 1000*320 | 100 spm | PP, HI PS, PET, PS, PLA |

Bidiyon Samfura

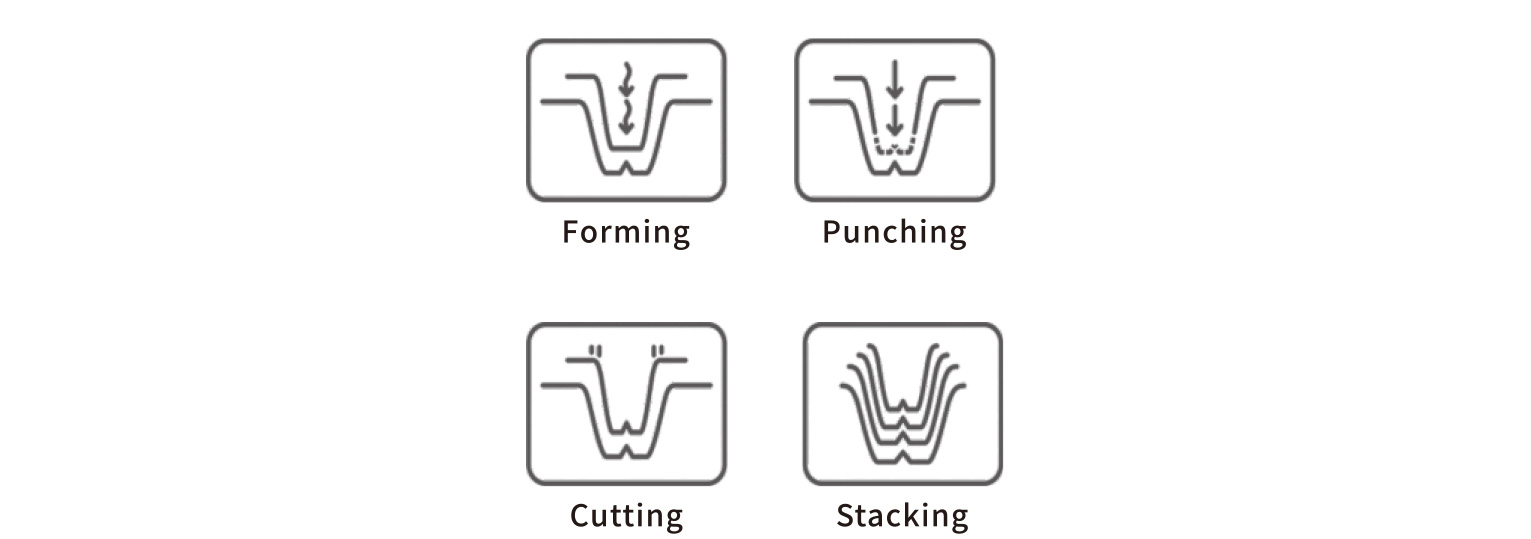

Tsarin Aiki

Babban Siffofin

✦ Ingantacciyar samarwa: Babban na'ura mai sarrafa thermoforming yana ɗaukar hanyar aiki na layin samar da ci gaba, wanda zai iya ci gaba da kammala aikin gyare-gyaren samfurin. Ta hanyar tsarin sarrafawa ta atomatik da kuma aikin injiniya mai sauri, za a iya inganta aikin samar da kayan aiki sosai don saduwa da bukatun samar da taro.

✦ Ayyukan aiki da yawa: injin yana da ayyuka da yawa kamar su ƙirƙira, naushi, bugun gefen da palletizing.

✦ Madaidaicin gyare-gyare da samfuran inganci: Babban injin thermoforming yana ɗaukar fasahar gyare-gyaren ci gaba, wanda zai iya daidai sarrafa zafin dumama, matsa lamba da lokacin dumama don tabbatar da cewa kayan filastik sun narke sosai kuma an rarraba su a ko'ina a cikin ƙirar, ta haka ne ke kera samfuran tare da ingancin saman ƙasa da daidaiton girman.

✦ Aiki ta atomatik da sarrafawar hankali: Injin yana sanye da tsarin aiki mai sarrafa kansa sosai, wanda zai iya aiwatar da ayyuka kamar ciyarwa ta atomatik, ƙirƙirar atomatik, naushi ta atomatik, bugun gefen atomatik da palletizing ta atomatik. Aikin yana da sauƙi kuma mai dacewa, yana rage sa hannun hannu, haɓaka haɓakar haɓakawa sosai da rage farashin samarwa.

✦ Tsaro da Kariyar Muhalli: Babban tsarin thermoforming inji an yi shi da kayan inganci, wanda ke da inganci mai kyau da kwanciyar hankali. Hakanan an sanye shi da tsarin kariya don tabbatar da amincin masu aiki. A lokaci guda kuma, na'urar tana da ƙirar ceton makamashi, wanda zai iya rage yawan amfani da makamashi da kuma rage tasirin muhalli.

Yankin Aikace-aikace

Babban tsarin thermoforming inji RM-T1011 thermoforming inji ana amfani dashi sosai a cikin masana'antar dafa abinci, masana'antar shirya kayan abinci da masana'antar kayan gida. Saboda babban ingancinsa, ayyuka da yawa da kuma daidaitattun siffofi, zai iya saduwa da bukatun masana'antu daban-daban don samfurori na filastik da kuma samar da goyon baya mai karfi ga kamfanoni don inganta haɓakar samar da kayan aiki da ingancin samfurin.

Koyarwa

Shirye-shiryen Kayan aiki:

Don fara injin ɗin ku, amintaccen ingantaccen na'ura mai sarrafa thermoforming RM-T1011 ta hanyar tabbatar da amintaccen haɗin sa da kunna shi. Cikakken bincike na dumama, sanyaya, da tsarin matsa lamba yana da mahimmanci don tabbatar da ayyukansu na yau da kullun. Tsare tsarin samar da ku ta hanyar shigar da gyare-gyaren da ake buƙata sosai, tabbatar da angan su don aiki mai santsi.

Shirye-shiryen Danyen Kaya:

Samun kamala a cikin ma'aunin zafi da sanyio yana farawa tare da shirye-shiryen albarkatun ƙasa na musamman. A hankali zaɓi takardar filastik mafi dacewa don yin gyare-gyare, kuma tabbatar da girmansa da kaurinsa sun daidaita tare da takamaiman buƙatun ƙira. Ta hanyar kula da waɗannan cikakkun bayanai, kun saita mataki don samfuran ƙarshen maras kyau.

Saitunan zafi:

Buɗe haƙiƙanin yuwuwar aikin thermoforming ɗinku ta hanyar ƙwararriyar daidaita zafin dumama da lokaci ta hanyar kula da panel. Daidaita saitunanku don dacewa da kayan filastik da buƙatun ƙira, samun sakamako mafi kyau.

Ƙirƙirar - Huɗa Hole - Punching Edge - Stacking and Palletizing:

A hankali sanya farantin robobin da aka rigaya ya yi zafi a kan gyaɗaɗɗen ƙura, tabbatar da an daidaita shi daidai kuma ba shi da duk wani wrinkles ko murdiya wanda zai iya yin lahani ga tsarin samarwa.

Fara tsarin gyare-gyaren, a hankali yin amfani da matsa lamba da zafi a cikin ƙayyadadden lokaci don siffata takardar filastik daidai cikin sigar da ake so.

Da zarar an gama ƙirƙirar, za a bar sabon samfurin filastik don ƙarfafawa da sanyi a cikin ƙirar, kafin a ci gaba zuwa naushin ramin, bugun gefen, da tari bisa tsari don dacewa da palleting.

Fitar da Kayan da Aka Kammala:

Bincika kowane samfurin da aka gama da kyau don tabbatar da ya dace da sifar da ake buƙata kuma ya bi ƙaƙƙarfan ƙa'idodin inganci, yin kowane gyare-gyare masu mahimmanci kamar yadda ake buƙata.

Tsaftacewa da Kulawa:

Bayan kammala aikin masana'anta, kunna na'ura mai sarrafa thermoforming kuma cire haɗin shi daga tushen wutar lantarki don adana makamashi da kiyaye aminci.

Tsaftace tsaftar da kayan aikin don kawar da sauran robobi ko tarkace, adana tsawon rayuwar gyaggyarawa da kuma hana lahani ga samfuran nan gaba.

Aiwatar da tsarin kulawa na yau da kullun don dubawa da sabis na kayan aikin kayan aiki daban-daban, tabbatar da cewa injin thermoforming ya kasance cikin yanayin aiki mafi kyau, haɓaka inganci da tsawon rai don ci gaba da samarwa.